- Commercial aviation

- Innovation

- Solutions

Engineering a solution for aircraft range extension fuel tanks

Reading time: 3 minutes

Client Challenge: design a new auxiliary fuel tank for the A220 aircraft

Given the complexity of supply chains in the aerospace industry, Hutchinson’s clients are often looking for solutions that will improve performance while helping to streamline their procurement and logistics.

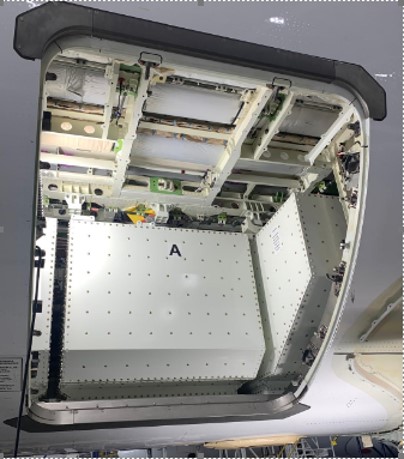

This was the case when the national subsidiary of a global aircraft manufacturer approached Hutchinson with a problem: it needed to develop an additional tank to enable range extension for the A220 ACJ. Hutchinson was tasked with supplying a new auxiliary aircraft tank. Our added value was to design one that required no internal bladder, while maintaining the same levels of safety and robustness.

Our Solution: a bladderless tank that simplified the supply chain

Traditional Airbus fuel tanks typically feature a bladder system inside a metallic structure. This bladder is used to prevent fuel leakage, creating a double-wall element for safety. When we launched this project, no bladderless fuel tank existed on the market. Creating one would be challenging, but we believed our engineers could do it.

Hutchinson has been creating solutions for the aircraft industry for more than 100 years. We understand the regulations governing safety and production standards, so it was no surprise that our client required us to use only its pre-approved materials. What’s more, our solution could not impact the production of any other parts of the aircraft, avoiding any knock-on effects of switching to a new tank design.

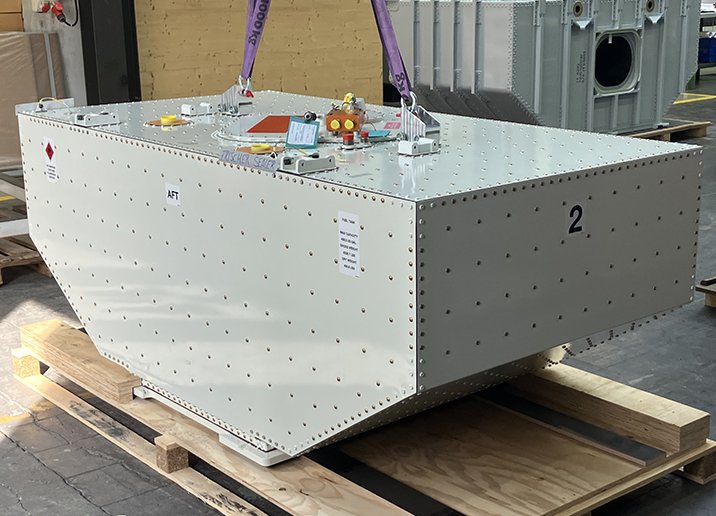

Hutchinson’s solution was the A220 ACT, an auxiliary aircraft fuel tank that needs no bladder, employing a fully metallic structure that enhances reliability and robustness, while simplifying production and reducing logistical complexities.

Customer benefits: robust, safe solution using pre-approved material

Using pre-approved materials, our engineers were able to design a fully metallic, double wall solution that delivered on each of our client's demands without introducing unnecessary costs, new materials, or affecting the design of any other part of the aircraft.

- Robust auxiliary fuel tank using pre-approved materials

- Bladderless system, simplifying supply chain

- Rapid response to client needs meeting stringent safety criteria

- No other design changes required to aircraft

Results: range extension without complex logistics

The A220 ACT has been rolled out to our customer, providing a range-extension solution that requires no internal bladder, thereby overcoming production delays caused by supply chain issues with this part. The new tank design delivers the necessary safety and robustness required by our customer while simplifying logistics and introducing no complications to the production of the aircraft.

Creating innovations that add value without increasingly complexity is one of the many things that Hutchinson does for clients across the most demanding industries in the world. We deliver solutions that help them to operate in safer, smarter, and more sustainable ways.

What challenge is holding up your business? Hutchinson has a team of over 40,000 problem solvers based in 25 countries and we’re waiting for your next challenge. Get in touch to see how our innovations can take your business to the next level.