- Automotive

- Solutions

- Innovation

Engineered solutions for e-compressor isolation

Reading time: 3 minutes

The automotive industry's rapid shift towards electric vehicles (EVs) presents unique challenges. One key area is the effective isolation of electric air compressors – essential for thermal management in all vehicles. As one of the world’s leading experts in vibration control, Hutchinson has devised an innovative approach to addressing the vibration issues inherent in these systems, ensuring optimal performance and passenger comfort.

Our deep understanding of vibration dynamics, coupled with in-house design, manufacturing and testing capabilities, allows us to deliver tailored solutions that perfectly match client expectations.

Client challenge: create a solution that minimizes compressor vibration in BEVs

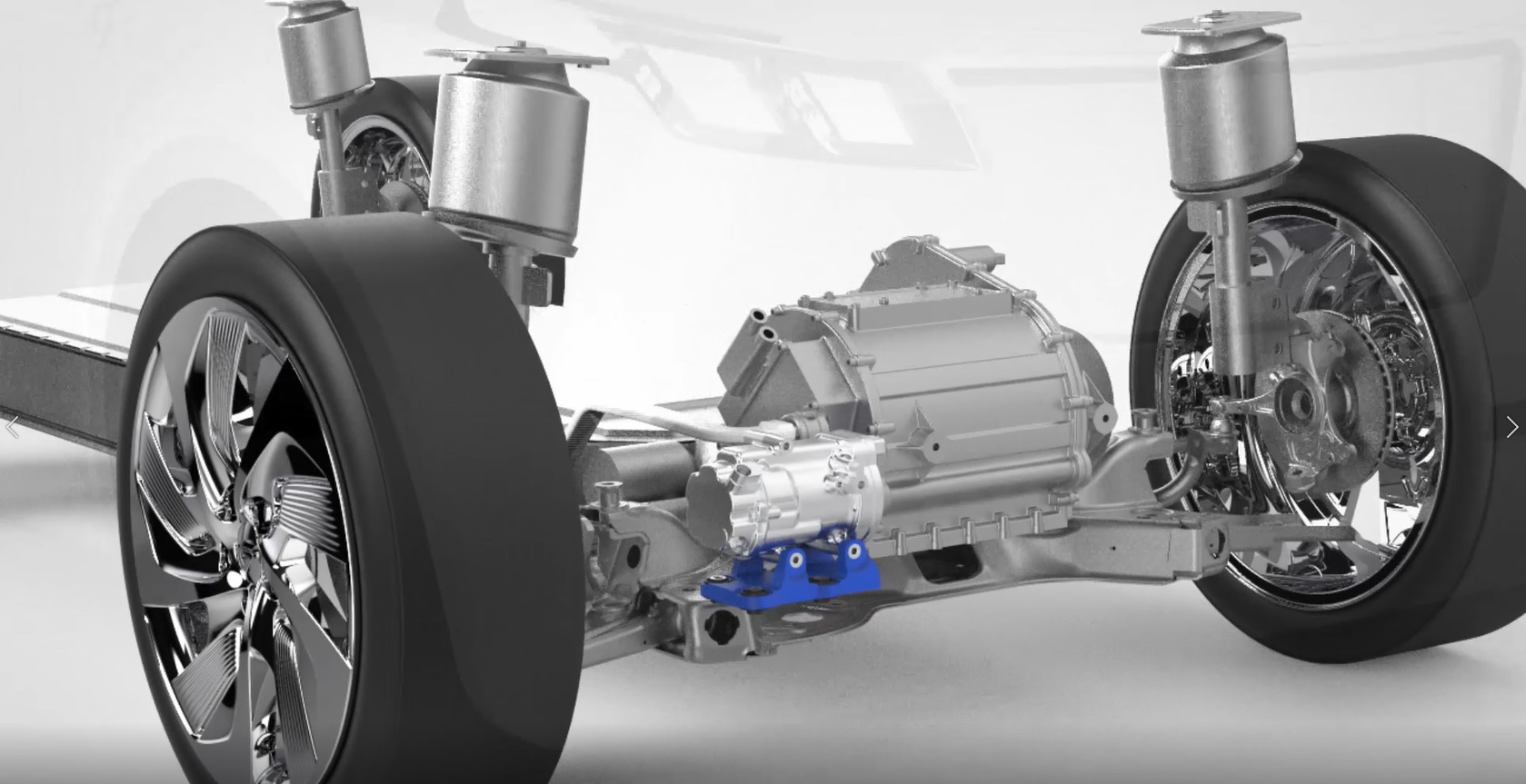

Traditional internal combustion engine (ICE) vehicles utilize belt-driven compressors directly linked to the engine. However, EVs require independent e-compressors, introducing new vibration challenges. The e-compressor's rotating components, combined with the electric motor's operation, generate vibrations that can impact the vehicle's performance and passenger experience.

Hutchinson has the scientific expertise to design custom solutions that mitigate these effects, offering OEMs a robust, secure and cost-optimized way to mount and isolate a vehicle’s compressor.

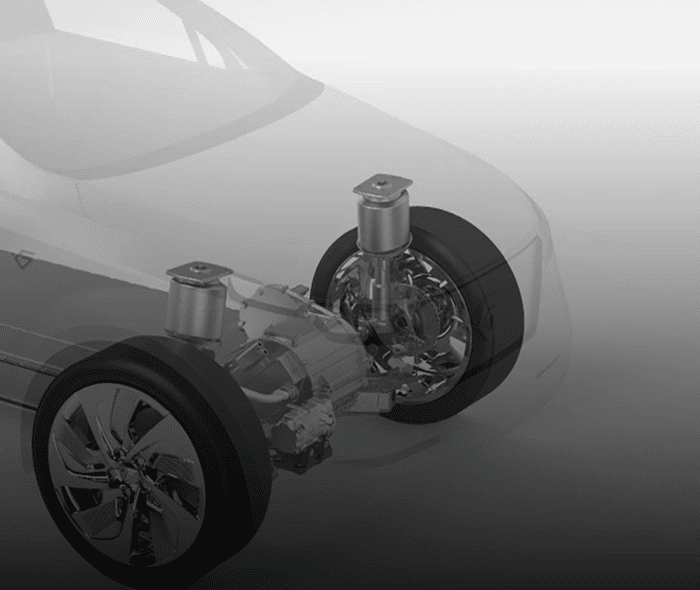

Our solution: flexible, durable e-compressor isolator brackets

Our e-compressor brackets are highly flexible and can be designed to the precise needs of each OEM. As a global expert in materials science, we are able to engineer materials with the specific characteristics required by our OEM partners. We offer single or double filtration architecture to ensure optimal isolation. Our rubber bushes can be designed to the precise dimensions required by each client and bracket assemblies are available in steel, aluminum, or plastic.

As a full-service engineering company, Hutchinson manages not only the design of our e-compressor brackets but also their manufacturing and testing, delivering finished products to our clients that are tailored perfectly for each vehicle. By managing all aspects of the system's design and manufacturing, Hutchinson ensures an optimized solution that maximizes performance without unnecessary cost. Our experts perform meticulous system analysis on each new design, allowing us to optimize the performance of our e-compressor brackets, defining the best mount positions and characteristics.

Client benefits: weight-savings in a fully assembled product

We leverage computer-aided engineering (CAE) and our simulation tools to ensure our solutions meet each client's specifications.

- High quality, durable and safe solution

- Lightweight – improving vehicle range

- Bracket material can be tuned to specific performance under different loads

- Brackets validated at in-house testing facilities

- Rapid response to specific customer requirements

- Fully assembled solution reducing procurement cost and complexity

Results: robust, secure, and cost-optimized compressor isolation

Hutchinson is able to provide OEMs with a complete, integrated solution, eliminating the need for multiple suppliers and streamlining the procurement process. This saves both time and reduces overall project costs for OEMs. By providing a fully assembled isolation system, we also reduce the burden on our clients' assembly lines.

As electrification continues to expand into commercial vehicles, agricultural machinery, and other industrial applications, Hutchinson is well-positioned to partner with OEMs from all sectors to deliver tailor-made solutions for mounting and isolating e-compressors. With a global presence in 25 countries, across four continents, we are ready to work side-by-side with our clients to deliver tailor-made solutions to their most technically demanding requirements.

Our comprehensive approach, integrated design capabilities, and rigorous testing procedures ensure that our clients receive a high-quality, cost-effective, and sustainable solution that meets their specific requirements and contributes to a more comfortable and efficient driving experience.